An effective product safety and compliance program can reduce accidents and product recalls, increase the safety and quality of products for consumers, and ensure market access worldwide. If you have not implemented a product safety and compliance program at your company yet, now is the time to get started.

Product safety is more than a job title or a department, it is a culture - and all employees should keep safety top of mind. Product safety and compliance affects engineering, manufacturing, purchasing, quality, parts, sales, and field service. So what are the first steps a small-to-mid-sized manufacturing company needs to take to establish the organizational structure and governance necessary for a product safety and compliance program?

1. Audit your current processes to determine the scope of work, hazards and requirements. During this first phase of the process, you may want to seek product liability legal help to analyze any previous claims and litigations, as well as the most immediate areas to address. Use risk elimination scales to determine the frequency, vulnerability and severity of your product’s risks. Develop a list of action items and track them in a closed loop system to ensure they are completed.

2. Identify key roles and the reporting structure of those roles. The number of people who will need to be involved will vary based on the size of your company, the level of risk from your company’s products and the amount of risk your company is willing to assume. Whether or not your company requires a full-time product safety manager or director, you should consider what types of additional training will be necessary to meet the responsibilities of the position(s).

3. Develop policies, procedures, standards and guidelines. All of these documents must be discoverable, scalable and attainable.

- Policies are clear, simple statements of how your organization intends to conduct its services, actions or business. They provide a set of guiding principles to help with decision-making.

- Procedures are the specific methods employed to express policies applied through actions in the day-to-day operations of the organization.

- Standards are documents that provide requirements, specifications, guidelines or characteristics that can be used consistently to ensure that materials, products, processes and services are fit for their purpose. Standards can be both internal and external.

- Guidelines are best practices that improve productivity and enhance safety, but are not as strict as standards.

The most crucial part of establishing your product safety and compliance program is making sure it is something you can maintain. At a basic level, a product safety and compliance program should include an accident recording and investigation process, a compliance verification process and risk assessment with protective measures to reduce risk.

If you feel like the expertise of your internal team is not enough, there is nothing wrong with seeking help from a third party. Bringing in a consultant is a great way to get your product safety and compliance program off the ground or audit your current program for effectiveness.

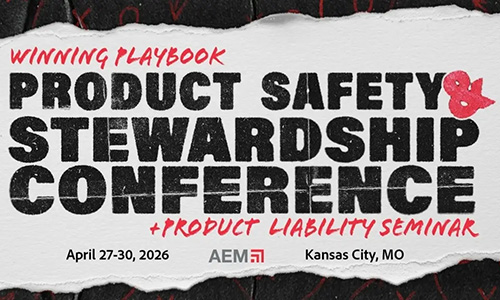

Set for April 22-25, 2024, in Rosemont, Illinois, AEM’s Product Safety & Stewardship Conference and Liability Seminar is the industry’s only annual conference dedicated to advancing heavy equipment manufacturing programs with custom-crafted education tracks, innovative approaches to product stewardship, and networking.

Subscribe to the AEM Industry Advisor for more safety and technical updates.